Calculating Solar PV String Size – A Step-By-Step Guide

One aspect of designing a solar PV system that is often confusing, is calculating how many solar panels you can connect in series per string. This is referred to as string size.

If you are unfamiliar with the terms “series” and “string”, it could be a good idea to head over to our article Introduction to Electricity for Solar PV Systems to get familiar with the electrical terminology used in solar.

String size is important, because if you connect too many panels per string, you run the risk of damaging your inverter. On the other hand, if you have too few panels per string, the inverter may shut off during the hottest days of the year, meaning you miss out on valuable generation time.

This article will focus on calculating string size when using string inverters or charge controllers. If you are planning to use DC optimizers or Micro-inverters in your system then this information does not apply. Optimizers and micro-inverters have specific rules around how many panels can be connected to them, and how they can be connected together. The rules vary between manufacturers and components, and can be found in the manufacturer design guidelines and product datasheets.

There are two main steps in calculating string size.

- What is the maximum string size possible?

- What is the minimum string size possible?

1. Calculating maximum string size

The maximum number of solar panels you can connect in a string is determined by the maximum input voltage of your inverter or charge controller. You can find this value on the inverter datasheet.

If the maximum input voltage of your inverter is exceeded on a cold day, the inverter can be damaged. Even if the inverter is not damaged by over voltage, having too many panels in a string may void the inverter warranty, so that you are not covered for other inverter issues.

To make sure you don’t exceed the maximum voltage of your inverter, the first thing you need to understand is how the voltage of the solar panels changes with temperature.

Understand temperature coefficients

The voltage of a solar panel is not fixed. As the temperature of a panel increases, its voltage decreases, and as its temperature decreases, its voltage increases.

The rate at which the open circuit voltage of a solar panel will change as its temperature changes is defined by the Temperature Coefficient of Voc. You can always find this value on the solar panel datasheet.

The temperature coefficient will be given in %/°C, (percentage per degree celsius). That is, is the percentage that Voc will rise, for every degree celsius the temperature of the panel drops.

For example, if you have a solar panel that has a Voc (at STC) of 40V, and a Temperature Coefficient of 0.27%/°C. Then for every degree celsius drop in panel cell temperature, the voltage will rise by:

40V x 0.27% = 0.108V

Or if your calculator doesn’t have a % sign

40V x 0.0027 = 0.108V

Since STC is at 25°C, then at 24°C, the new Voc would be 40.108V.

Some datasheets will give the temperature coefficient in mV/°C. In this case you can convert to %/°C by dividing the mV/°C figure by the Voc value. Just be sure to convert from mV to V first.

For example if

Voc = 41.5

Temp Coeff of Voc = -107.9 mV/°CTemp Coeff of Voc (in %/°C) :

(-107.9 ÷ 1000) ÷ 41.5V = -0.0026 = -0.26%/°C

Find the lowest expected temperature at your location

Since you need to find your maximum string voltage, and you know that voltage increases as temperature decreases, you need to find out what your lowest expected temperature is.

Luckily there are standards that tell you how to calculate this number, and websites that will tell you which temperature to use at your location.

Firstly, the temperature you need to use is the mean of annual extreme low temperatures, or to put it another way, it is the average of all the coldest temperatures from previous years. This is the figure recommended both by the NEC.

To find this temperature at your location, you can use one of the following:

In the USA: SolarABCs

Find the weather station nearest your location and take the value for Extreme Min – This is actually the mean figure you need.

In the rest of the world: http://ashrae-meteo.info/v2.0/

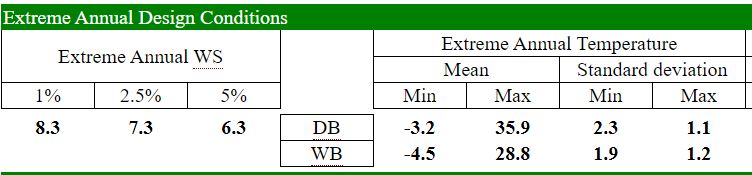

Find your location on the map, right-click to select your location, then left-click on the weather station closest to you. Then scroll down to find the value in the table (-3.2°C in the example below):

If for some reason you cannot find the mean low temperature for your location, an alternative is to use the lowest historical temperature instead. This is a little more conservative, but will always be within the standards and warranty requirements.

Calculate the maximum voltage of one panel

So now you know the solar panel Voc and Temperature coefficient, and the lowest expected temperature for your location. You can now calculate the voltage of a panel at that temperature, which is the maximum voltage of one panel.

Assume you had the following values:

Voc(STC): 41.5V

Temperature coefficient of Voc : -0.26 %/°C

Expected low temperature: -5°C

First, find the difference between STC temperature (25°) and your expected low temperature

25°C – (-5°C) = 30°C

Multiply this by the temperature coefficient. Ignore the – sign, since you are only looking for the change in Voc here

30°C x 0.26% = 7.8%

Or 30°C x 0.0026 = 0.078

Now increase Voc(STC) by this percentage

41.5V x (1+0.078) = 44.737V

(You may see calculations elsewhere that look slightly different to this method, don’t be concerned as these are just different ways of showing the same thing, and (as long as they haven’t made an error!) should give the same results. The method here is an attempt to break this calculation down as simply as possible.)

Calculate the maximum panels per string for your inverter

Once you have the max Voc of one panel, all you have to do is divide your inverter maximum voltage by this value, and then round down to the nearest whole number.

For example, using the example above with a 600V inverter:

600V ÷ 44.737V = 13.41 panels

So this means if you connected 13.41 panels to your inverter you would be right at the inverter’s voltage limit. Now obviously you can’t have 0.41 of a panel, so you always round down to the nearest whole number. In this case, 13 panels per string is the maximum.

2. Calculating minimum string size

Now that you know what the maximum string size you can have is, you also need to calculate the minimum string size. Safety and inverter warranty are not a concern here like with maximum string size, but your inverter has a minimum input voltage which it can run at, and you want to make sure your inverter will continue to run on the hottest days of the year, or else you will be losing valuable generation.

The method is very similar to calculating maximum string size. The main differences are that Vmp is used instead of Voc, we have to choose a maximum temperature instead of a minimum temperature, and in the final step we have to round up instead of down.

Find the maximum ambient temperature for your site

When selecting a maximum temperature to use in the calculations, you can again use SolarABCs. You will see two options for High Temp, 0.4% and 2%. Select the 2% figure.

As with the minimum temperature, if you are unable to find the above values for your area, you can always use the highest recorded temperature instead. This will just give a more conservative (longer) minimum string size.

Calculate solar cell temperature

You now have the maximum ambient temperature for your location, but you also need to consider that solar panels operate at temperatures much higher than ambient. How much hotter they get depends on the mounting method, since this affects the ventilation of the panels. The following rules of thumb can be used.

For rooftop-mounted panels add 25°C

For ground-mounted panels add 30°C

So if we assume a roof-mounted system near Orlando International Airport, then from the image above our cell temperature is:

Cell temp = 34°C + 25°C = 59°C

Calculate the minimum voltage of one panel

Next, you need to calculate the minimum voltage of one panel.

Assume the following:

Vmp: 34.7V

Power Temperature coefficient: -0.34%/°C

First, find the difference between STC temperature (25°) and your expected high temperature

59°C – 25°C = 34°C

Multiply this by the temperature coefficient. Use the temperature coefficient for Vmp if it is on the datasheet, if not use the power temperature coefficient.

34°C x 0.34% = 11.56%

Or 34°C x 0.0034 = 0.1156

Now decrease Vmp by this percentage

34.7V x (1-0.1156) = 30.68868V

Calculate the minimum panels per string for your inverter

Lastly, divide the minimum MPPT voltage of the inverter by the minimum voltage you have just calculated.

Assuming an inverter with a minimum MPP voltage of 200V:

200V ÷ 30.69V = 6.517 panels

Here you have to round up to find the minimum number of panels, so using these components the minimum string size is 7 panels.

In this calculation, we have used the minimum MPPT voltage. Some other sources say to use the minimum operating voltage, this means that you are designing the system so that the inverter will always turn on, but the voltage may still be outside the MPPT range. You can do this if you have some specific reason for needing smaller strings, however ideally you should be using the minimum MPPT voltage to ensure that the inverter is always running optimally.

Have any questions? Let us know in the comments below.